how does a check valve work video

Because this can be hard to explain on paper we have developed a series of videos that will demonstrate the check valve. Whether it is manually or actuator operated some force moves the lever or handle to a quarter turn to open the valve.

Pilot Operated Check Valve Working In Hydraulic System Pilot To Open Pilot To Close Check Valve Youtube Hydraulic Systems Valve Pilot

An important concept in check valves is the cracking.

. The word CLOSE with an arrow is imprinted on the top of most Coleman pump handles. How does a check valve work. Once the system reaches the cracking pressure or the minimum upstream pressure needed for the valve to operate the disc will lift and allow the fluid to pass through.

Check valves are controlled based on a systems flow velocity. Depending on the device model the movement of the stick is either automated and controlled by a trigger or manually fed. In relation to gaseous processes check valves are often used when multiple gases are.

Because of their simple design check valves generally operate without automation or human interaction and. Our check andpressure relief valves provide accur. Under pressure fluids enter the valve at the inlet where they force the disc off the seat of the valve and exit through the outlet.

Sharing this knowledge with existing and potential customers can save them time and money as they develop their current or future applications. Flow continues steadily as long as the pressure is maintained to keep the disc open. Check valves are used to control the direction of system products flowThe system product flow is in one direction only.

If the fluid pressure decreases or if the flow direction starts to reverse the disc will automatically close the. This force is transferred to the stem moving the disc to open. Tilted check valves.

Has focused on the intricate details of how one-way check pressure relief valves work in low pressure low flow devices. The hot melt sticks mentioned above are usually loaded into a back cavity that exists on the gun. In this episode of Spec.

This video illustrates how a Double Check Valve Backflow Prevention Assembly functions. Swing check valves. The flow rate is also responsible for determining the rate of energy transfer at any specific level of pressure.

How They Work. They have two ports one as an inlet for the media and one as the output for the media. Valves like this slide back and forward to make fluid flow in either one direction or another around a circuit of pipes.

When the gun activates the glue moves to what is known as a check valve on the way to the melting chamber. Check valves are controlled based on a systems flow velocity. Check Valve Video - Part 1 - Where is the check valve and how does it work.

That little quirk gives us the video you see here which makes for a wonderful real. OVERVIEW OF WHITE PAPER. A check valve is an automatic safety device designed to allow fluids and gasses to flow in one direction and prevent reverse flow.

Since they only allow media flow in one direction they are commonly referred to as one way valves or non return. Sense Vance explains how check valves act as gates only letting water flow in one direction. This 3D animated video explains how a swing check valve works.

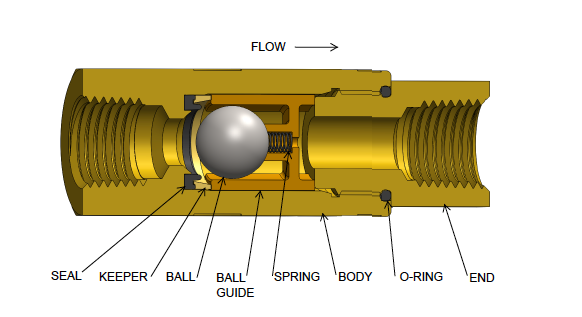

Ball check vales. Nozzle check valves. The ball disc turns and its hollowed side faces the flow of media.

A check valve also called a non-return valve is a mechanical device that normally allows fluid to flow through it in only one direction. When discussing check valve applications we must first consider the media being processed. Its not necessarily when the valve is in the fully open position.

This valve typically has a rubber or resilient seat and relies on the disc having a high level of contact with the seat to. For over 30 years Smart Products USA Inc. A check valve is a device that only allows the flow of fluids in one direction.

Check Valve - How They Work. The force of upstream fluid creates high differential pressure across the interior valve body and it then allows forward streams to pass through. If the fluid pressure decreases or if the flow direction starts to reverse the disc will automatically close the.

A clapper hangs from a hinge clapper shaft or pin mounted to the underside of the bonnet. Every so often the lid lifts up to release or admit liquid or gas. Once the system reaches the cracking pressure or the minimum upstream pressure needed for the valve to operate the disc will lift and allow the fluid to pass through.

Generally speaking the ball valve working mechanism works this way. At Smart Products we have over 3 millionflexible flow control solutions to meet aspecific design criteria. Plus thanks to the valve-in-block design you can run a flathead V8 with one of the cylinder heads removed.

Check valves also known as nonreturn or one-way valves enable fluid to flow one way in a pipeline. Resilient-seated butterfly valves are the most basic design and are also commonly called concentric or resilient-seated butterfly valvesIn this type of valve the stem is centered in the middle of the valve disc which is centered in the pipe bore. We look at all the main components of the swing check valve as well as how it operates.

This type of valve is like a lid sitting on top of a pipe. Spool valves regulate the flow of fluid in hydraulic systems. Figure below shows cutaway view of.

Turning the pump clockwise threads the air stems tip deeper inside the check valve until it is completely blocked. When you want to reseal a check valve youre looking to get the right resealing pressure in which theres no indication of flow through the valveno stream of bubbles. Since actuator speed determines the horsepower or energy.

Silent check valves. Turning it counterclockwise retracts the pointed tip from the check valve and allows air to flow past it. This design inhibits backflow in a line.

Check Valve Video - Part 2 - How do we know the check valve works. Dual disc check valves. A flow-control valve in any hydraulic system is tasked with the regulation of fluid speed and by regulating the rate it can control the speed of an actuator in the system.

Cracking pressure is that pressure at which you first get an indication of flow.

What Are Critical Check Valves Inspectioneering

Replacing Faulty Rv City Water Connection Weeping Check Valve Rv Valve Connection

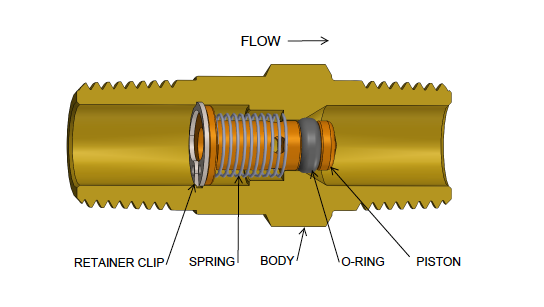

Spring Loaded Check Valves Check Valves Part Iii Ism

What Are Critical Check Valves Inspectioneering

How To Make A Check Valve Non Return Valve Working Principle Youtube

Check Valves A Tutorial Engineering360

How Do Check Valves Work Spec Sense Youtube

How To Choose The Right Check Valve Avk International

Check Valves A Tutorial Engineering360

Rv City Water Check Valve Disassembly And Repair Rv Rv Maintenance Repair

How To Install Swing Check Valves Vertically Or Horizontally

Water Quality In Your Home Single And Double Check Valves Youtube

The Importance Of Check Valves In Hydraulic Systems

Check Valve How It Works Youtube

Squealing Rv Water Heater Fix Failed Check Valve In This Video I Locate And Replace A Faulty Brass 1 2 Check Valve Rv Water Heater Rv Water Water Heater

Double Check Valve Backflow Prevention Assembly How It Works Valve Prevention Assembly

How To Make A One Way Check Valve For Cheap Youtube

Direct Acting Solenoid Valve Animation Valve Directions Engineering